-40%

Dialux Jewelry Polishing Compound 6 BARS Jewelers Rouge Polish Jewelry & Metals

$ 17.87

- Description

- Size Guide

Description

JEWELRY POLISHING COMPOUNDSD

i

a

l

u

x

®

POLISHING COMPOUNDS

ASSORTMENT

SET 6 Pcs

POLSHING COMPOUNDS - DIALUX

®

FRENCH

1 BAR EACH - A

SET OF

6

BARS

RED

/

BLUE

/

WHITE

/

GREEN

/

YELLOW

/

GRAY

DIALUX

®

Brand polishing compounds originally formulated in France has been a popular polishing compound for over 50 years.

The Dialux polishing compounds are a high grade premium polishing line of compounds specifically formulated for Precious Metals in Jewelry Polishing.

These are "Original" compounds not similar ones from CHINA

.

DIALUX SET

:

CUTTING - POLISHING & FINISHING COMPOUNDS

Bar size:

4" x 1" x 1-1/8"

-

100mm x 25mm x 30mm

Bar Weight:

120 Grams

-

4 Oz.

·

RED

"ROUGE DE PARIS"

-

Used for Super Finishing yellow color metals, especially Gold.

·

YELLOW

"JAUNE"

-

Used for Bright Shine on Brass - Copper - Bronze - Soft Metals - Non ferrous Metals

(

Note: The Yellow Dialux Bar color is actually a BROWN tone, the name & label is Yellow)

·

BLUE "BLEU DE PARIS"

-

Used for High Shine on all metals

·

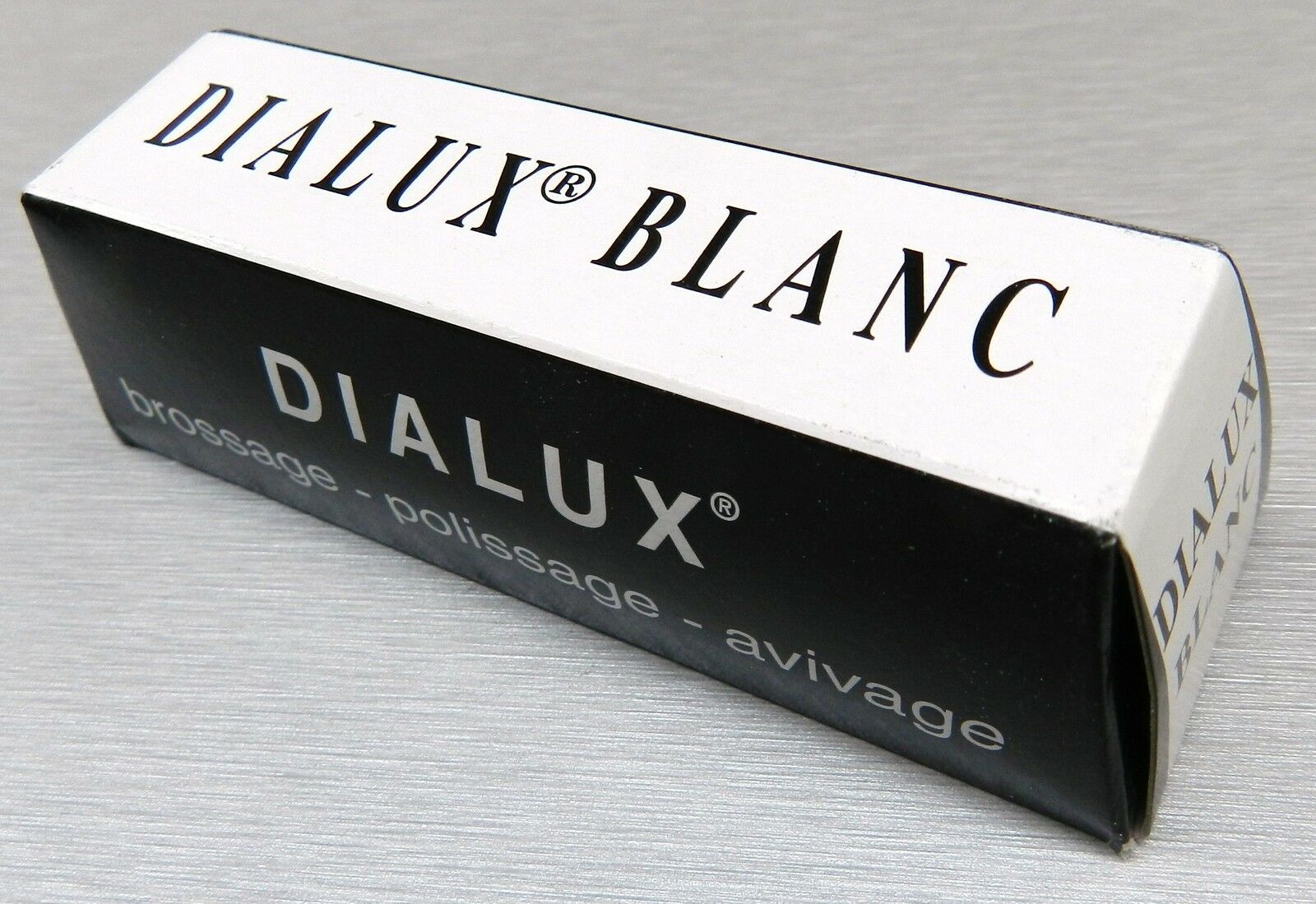

WHITE "BLANC"

-

Used for Bright Polish on White Metals - Silver

·

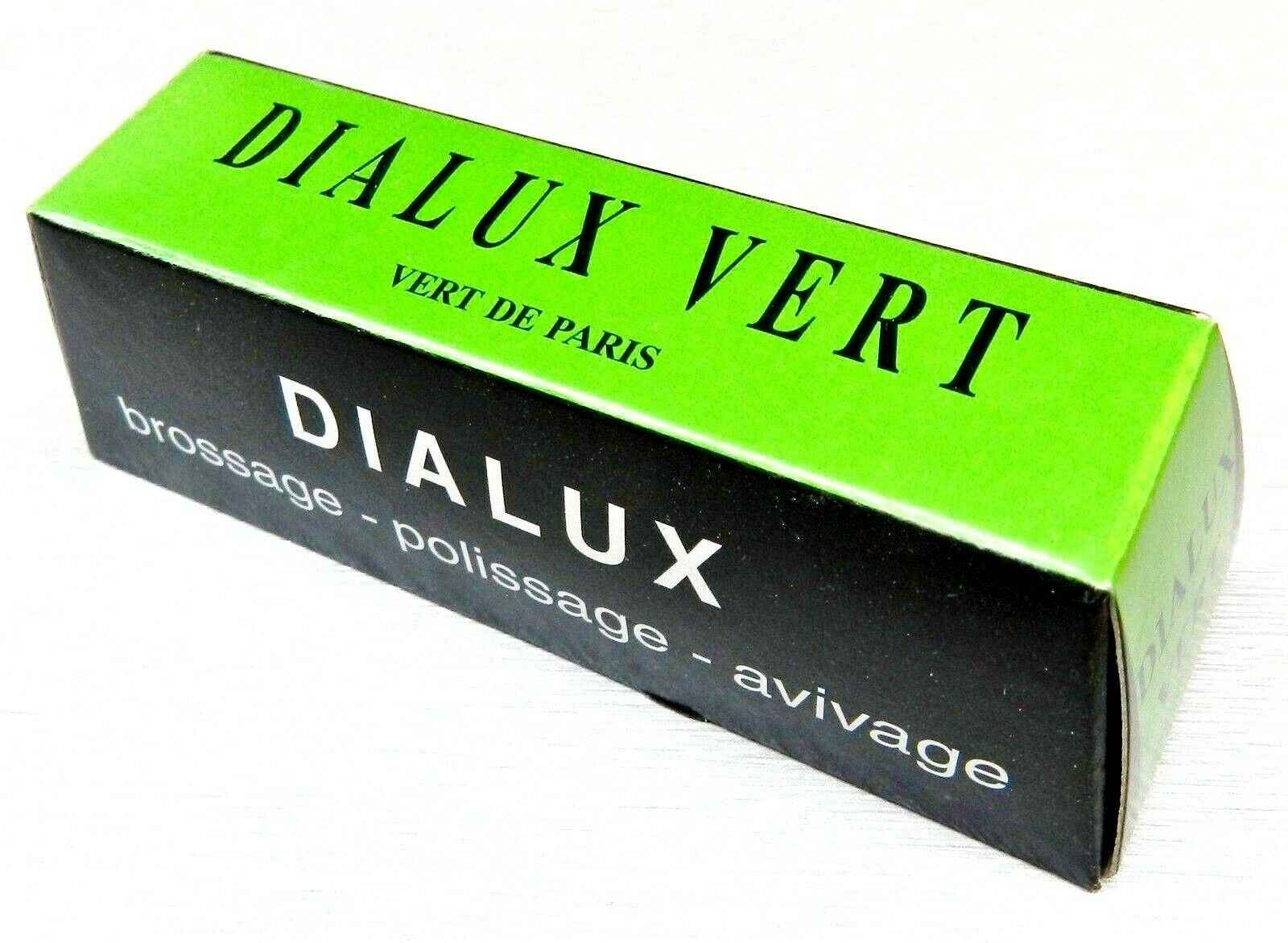

GREEN "VERT"

-

Used for Polishing Silver & White Color metals

·

GRAY

"GRIS"

- Used for Cutting & Semi-Polish for Stainless & Hard White Color metals.

NOTE:

We have included polishing recommendations at the bottom of this page, to assist you.

JETS Product # 1614-90234567

Made by Lippert/Unipol

SHIPPING: ViaUSPS MAIL Domestic via PRIORITY MAIL FLAT RATE Mail®

NOTE: Visit

JETSTOOLS

our

ebay Store Listings, where you can see INDIVIDUAL

D

i

a

l

u

x

®

Polishing Compounds along with Polishing and Buffing Wheels in various sizes and materials and a selection of

J

ewelers

E

quipment

T

ools

&

S

upplies

.

JETSINC.

POLISHING RECOMMENDATIONS

:

Our recommendations and suggestions on Buffing to obtain the best results possible:

·

Use the right compound for the metal that you are trying to polish

·

It may be needed to go through 2 or 3 steps, in polishing to get the optimum result you are looking to achieve.

·

Make sure that the parts that are being polished are smooth and clean, use the appropriate abrasive to remove lines and scratches.

·

Avoid using different compounds with the same buff, if you have to then make sure to clean and remove any hardened compound residue on the surface edge with a buff rake.

·

Segregate your buffs for the various metals, Gold, Silver, Brass … try not to use the same buff for all metals.

If you have to then make sure buffs are cleaned (dressed) with a buff rake.

·

A clean buffing wheel edge is important.

·

Allow the buff and compound to perform the work they were made and formulated for, excessive force or pressure will hurt the process

·

Whenever you are working with Platinum never use a buff that was used for another type of metal.

WORK SAFE!

Working with rotary motors and wheels can be dangerous if proper safety procedures are not followed

.

PROTECTION -

Protect yourself, your fingers and hands, your face and eyes and use respirators

.

28B int 312 CKSP Z M P